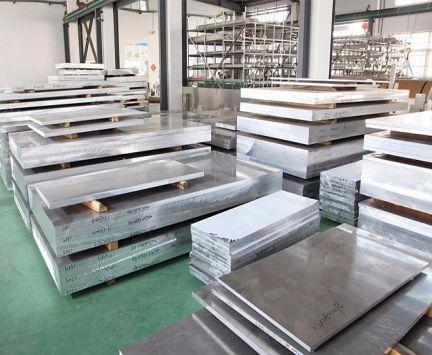

Aluminum manganese alloy series is a common product. Due to the manganese alloy element, this product has excellent antirust properties. Its strength is about 10% higher than that of 1100, and its formability, solubility and corrosion resistance are good.

Detailed introduction

About 3A21 Aluminium

As an Al Mn alloy, it is the most widely used antirust aluminum with low strength (only slightly higher than industrial pure aluminum) and cannot be heat treated and strengthened. Therefore, cold processing is often used to improve its mechanical properties; It has high plasticity in annealing state, and is good in semi cold hardening, low plasticity, good corrosion resistance, good weldability and poor cutting performance.

Chemical Composition and Mechanical Property

Al | Si | Cu | Mg | Zn | Mn | Ti | Ni | Ti+Zr | Fe |

Margin | ≤0.60 | ≤0.20 | ≤0.50 | ≤0.10 | 1.00-1.60 | ≤0.15 | --- | ≤0.20 | ≤0.70 |

Tensile Strength(Mpa) | 140-180 |

yield strength(Mpa) | ≥115 |

EL(%) | ≤2% |

Density(g/cm³) | 2.75 |

Applications for 3A21 Aluminium

It is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other low load parts made by deep drawing: wire rod is used for rivets. 3003 aluminum sheet has good formability, solubility and corrosion resistance. It is used to process parts with good formability, high corrosion resistance and good weldability, or work with these properties and higher strength than 1xxx alloy, such as kitchen utensils, food and chemical products processing and storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic plates, etc Photocopier cylinder, ship material.

Heat treatment for 3A21 Aluminium

1) Homogenization annealing: 510 ~ 520 ℃; Heat preservation for 4-6h; Air cooling.

2) Rapid annealing: 350-410 ℃; With the different effective thickness of the material, the holding time is 30-120 min; Air or water cooled.

3) High temperature annealing: 350-500 ℃; When the thickness of the finished product is more than or equal to 6 mm, the heat preservation time is 10-30 min, and when the thickness is less than or equal to 6 mm, the heat penetration is complete; Air cooling.

4) Low temperature annealing: 250-300 ℃; The heat preservation time is 1-3 H; Air or water cooled.

State: aluminum and aluminum alloy profiled plate (0.6-0.8mm, hx8 state)