It is a kind of duralumin alloy material, the main chemical composition is zinc, iron, magnesium, aluminum, etc., with good machinability, good resistivity, spot welding and seam welding performance.

Detailed introduction

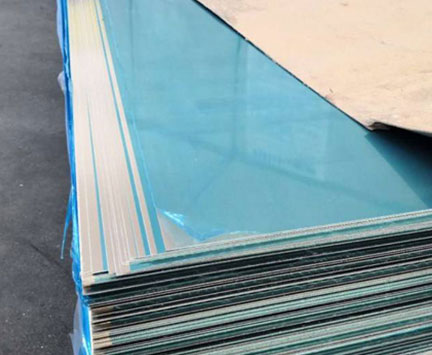

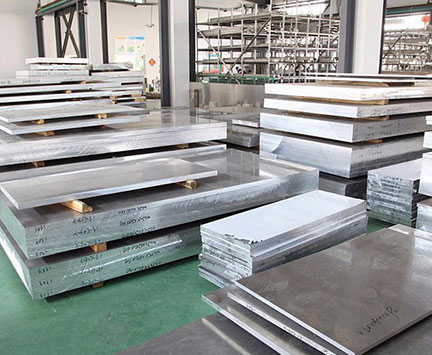

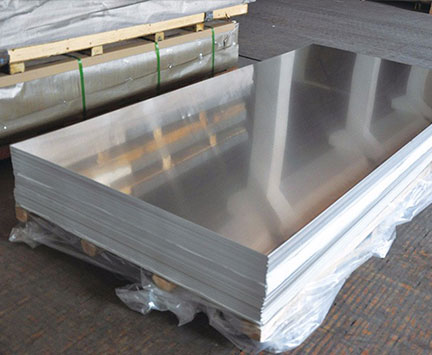

About 2A14 Aluminum

It is a kind of duralumin alloy material, the main chemical composition is zinc, iron, magnesium, aluminum, etc., with good machinability, good resistivity, spot welding and seam welding performance.

Chemical Composition and Mechanical Property

Al | Si | Cu | Mg | Zn | Mn | Ti | Ni | Fe+Ni | Fe |

Margin | 0.60-1.2 | 3.9-4.8 | 0.4-0.8 | ≤0.30 | 0.40-1.0 | ≤0.15 | ≤0.10 | --- | ≤0.70 |

Tensile Strength(Mpa) | ≥440 |

yield strength(Mpa) | ≥235 |

EL(%) | ≥10% |

Density(g/cm³) | 2.68 |

Heat treatment

1) Homogenization annealing: 475 ~ 490 ℃; Heat preservation for 12-14h; The furnace is cold.

2) Complete annealing: 350-400 ℃; With the different effective thickness of the material, the holding time is 30-120 min; At the speed of 30-50 ℃ / h, it is cooled to 300 ℃ with the furnace, and then air cooled.

3) Rapid annealing: 350-460 ℃; The heat preservation time was 30-120 min; Air cooling.

4) Quenching and aging: quenching 495 ~ 505 ℃, water Cold; Natural aging at room temperature for 96 h.

Applications for 2A14

It is widely used in rivets, missile components, truck hub, propeller components and other structural parts of aircraft structures (skin, skeleton, rib, partition frame, etc.)

Used as structural rivets with working temperature not exceeding 100 ℃.

Aircraft heavy, forging, plate and extrusion materials, wheels and structural elements, first stage fuel tank and spacecraft parts of multistage rocket, truck frame and suspension system parts.