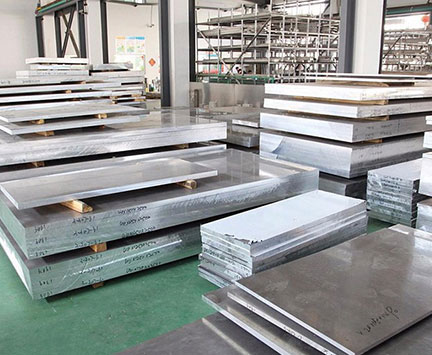

Aluminum alloy 1050 is industrial pure aluminum, which has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but its strength is low, heat treatment can not strengthen, and its machinability is poor

Detailed introduction

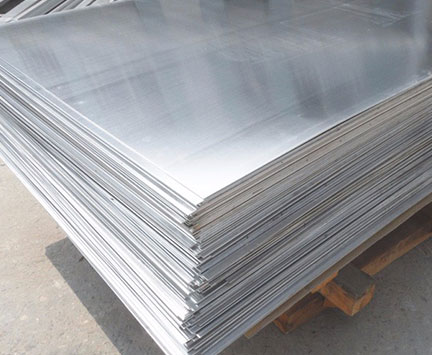

About 1050 Aluminum

Aluminum alloy 1050 is industrial pure aluminum, which has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but its strength is low, heat treatment can not strengthen, and its machinability is poor; It can be gas welding, hydrogen atom welding and contact welding, not easy to braze; Easy to bear all kinds of pressure processing and drawing, bending.

Chemical Composition and Mechanical Property

Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe |

99.50 | ≤0.25 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | ≤0.05 | 0.00-0.40 |

Tensile Strength(Mpa) | 60-100 |

EL(%) | ≥23 |

Density(g/cm³) | 2.68 |

Heat treatment specification for 1050

1) Complete annealing: 390-430 ℃; With the different effective thickness of the material, the holding time is 30-120 min; At the speed of 30-50 ℃ / h, it is cooled to 300 ℃ with the furnace, and then air cooled.

2) Rapid annealing: 350-370 ℃; With the different effective thickness of the material, the holding time is 30-120 min; Air or water cooled.

3) Quenching and aging: quenching 500 ~ 510 ℃, air cooling; Artificial aging 95 ~ 105 ℃, 3 h, air cooling; Natural aging 120h at room temperature.

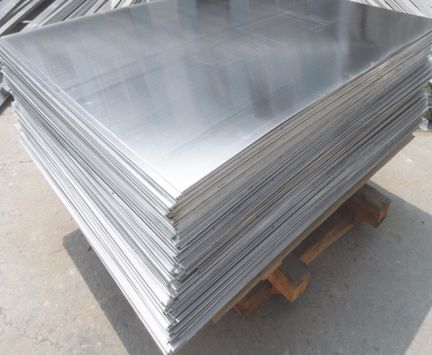

Characteristics for 1050

Industrial pure aluminum has the general characteristics of aluminum, with small density, good conductivity, heat conduction, good corrosion resistance and good plastic processing performance. It can be processed into plates, strips, foil and extruded products, and can be used for gas welding, argon arc welding and spot welding.

The industrial pure aluminum can not be heat treated and strengthened, and the strength can be improved by cold deformation. The only heat treatment form is annealing. The recrystallization start temperature is related to impurity content and deformation degree, generally about 200 ℃. Annealed sheet σ b=80~100MPa, σ 0.2=30~50MPa, ζ= 35%~40%,HB=25~30. After 60% - 80% cold deformation, the disorder can be increased to 150-180mpa, but ζ The value of the value decreased to 1% ~ 1.5%. The increase of iron and silicon impurities can improve the strength, but reduce the plasticity, conductivity and corrosion resistance. The mechanical properties of 1200 (L5) industrial pure aluminum plate can be obtained by adjusting the annealing temperature or controlling the cold deformation. In order to improve formability, the former method is better.

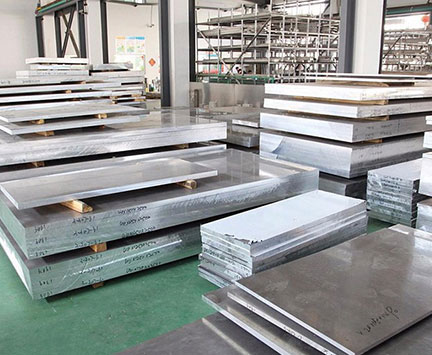

Applications for 1050

1050 aluminum is often used in daily necessities, lighting appliances, reflective plates, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some occasions where both corrosion resistance and formability are required, but the strength requirement is not high, chemical equipment is its typical use.

Online Message

- No Prev

-

- NEXT >